[ad_1]

Because the world is transferring towards a extra sustainable future, the demand for clear power is rising quickly, which has given delivery to the manufacturing of inexperienced ammonia, a carbon-free gas that has gained vital consideration. Nevertheless, the manufacturing of inexperienced ammonia requires a dependable and environment friendly supply of hydrogen. That is the place proton alternate membrane (PEM) electrolyzers come into play.

PEM electrolyzers are thought of the spine of the inexperienced ammonia transition as a result of they supply a clear and environment friendly approach to produce hydrogen from renewable sources of power, similar to wind and solar energy.

Additional on this article, we’ll focus on the workings of PEM electrolyzers and discover their function in facilitating the transition to a inexperienced economic system via ammonia manufacturing and their software in a number of different sectors.

What’s PEM electrolysis?

PEM electrolysis is a course of that makes use of an electrochemical cell to separate water (H2O) into its constituent components of hydrogen (H2) and oxygen (O2) utilizing an utilized electrical voltage. The electrolysis happens in a specialised membrane cell that’s designed to permit protons to cross via whereas stopping the migration of electrons, which might in any other case produce undesirable byproducts.

The method entails the appliance of {an electrical} present to the cell, which splits the water molecule into hydrogen ions (protons) and oxygen ions. The hydrogen ions then cross via the membrane to the anode, the place they’re mixed with electrons to kind hydrogen fuel. In the meantime, the oxygen ions transfer to the cathode, the place they mix with electrons to kind oxygen fuel.

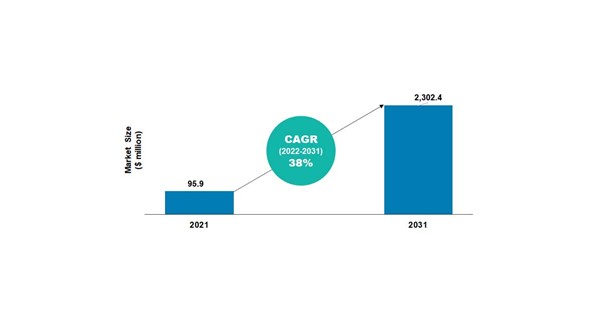

In keeping with the BIS Analysis report, the PEM electrolyzer market is projected to achieve $2,302.4 million by 2031 from $95.9 million in 2021, rising at a CAGR of 38% in the course of the forecast interval 2022-2031.

To get extra data, obtain this FREE pattern report.

PEM electrolysis is usually most well-liked over different electrolysis strategies because of its excessive effectivity, quick response instances, and low working temperatures. It additionally has the benefit of having the ability to produce high-purity hydrogen with out the necessity for extra purification steps. This makes PEM electrolysis a beautiful possibility for producing hydrogen from renewable power sources similar to photo voltaic and wind energy, which can be utilized to energy gas cells or produce inexperienced ammonia.

What’s the means of ammonia manufacturing via PEM electrolysis?

Ammonia (NH3) is just not immediately ready from PEM electrolysis. As a substitute, ammonia is produced via a course of known as nitrogen fixation, which mixes hydrogen and nitrogen fuel from the air to kind ammonia. The hydrogen fuel required for nitrogen fixation might be produced via PEM electrolysis.

The manufacturing of ammonia via a PEM electrolyzer entails the next steps:

Water electrolysis: In step one, water is electrolyzed utilizing a PEM electrolyzer to supply hydrogen fuel (H2) and oxygen fuel (O2). The PEM electrolyzer cell incorporates a proton alternate membrane, which permits the transport of protons whereas blocking the switch of electrons between the anode and cathode. An electrical present is utilized to the electrolyzer cell, which splits water into hydrogen ions (protons) and oxygen ions.

Purification of hydrogen fuel: The hydrogen fuel produced within the electrolysis step is purified to take away any impurities similar to moisture, carbon dioxide, and carbon monoxide. This step is vital to make sure the purity of the hydrogen fuel, which is important for the following ammonia synthesis step.

Nitrogen fixation: The purified hydrogen fuel is mixed with nitrogen fuel (N2) from the air to kind ammonia (NH3) via a course of known as nitrogen fixation. This step sometimes entails excessive strain and temperature circumstances, utilizing a catalyst to facilitate the response.

Separation and storage: The ammonia produced within the nitrogen fixation step is separated from any unreacted gases and impurities and saved for additional use.

The method of ammonia manufacturing via a PEM electrolyzer is an environment friendly and sustainable approach to produce ammonia with out utilizing fossil fuels. It makes use of renewable sources of power to supply hydrogen, which is then mixed with nitrogen from the air to kind ammonia. This course of can assist to cut back the carbon footprint of the ammonia manufacturing trade and contribute to the worldwide transition towards a extra sustainable and environmental pleasant economic system.

What are the foremost challenges and future outlooks for PEM electrolysis in ammonia manufacturing?

Whereas PEM electrolysis holds promise as a sustainable and environment friendly methodology for ammonia manufacturing, a number of challenges nonetheless should be addressed to make sure its widespread adoption within the trade.

Capital prices: PEM electrolysis methods have excessive capital prices, making them comparatively costly in comparison with conventional ammonia manufacturing strategies. This makes it tough for the know-how to compete on a value foundation with typical ammonia manufacturing strategies.

Sturdiness: PEM electrolysis methods require high-purity water and have strict working circumstances, which might result in degradation and diminished efficiency over time. This reduces the lifespan of the system and will increase the necessity for upkeep and alternative, resulting in increased prices.

Scale-up: Whereas PEM electrolysis methods are modular and might be scaled up or down relying on demand, scaling as much as industrial-scale manufacturing might be difficult because of technical and financial constraints.

Vitality storage: The intermittent nature of renewable power sources similar to photo voltaic and wind energy can pose a problem to the continual operation of PEM electrolysis methods. Vitality storage options similar to batteries and hydrogen storage can assist to deal with this situation, however additionally they add to the general price of the system.

Regardless of these challenges, the longer term outlook for PEM electrolysis in ammonia manufacturing is promising. Know-how is continually enhancing, with new developments to extend effectivity, cut back prices, and enhance sturdiness. Advances in supplies science and engineering are anticipated to result in the event of extra environment friendly and sturdy membranes and electrodes, which can improve the efficiency and lifespan of PEM electrolysis methods. Moreover, the rising availability of renewable power sources is predicted to drive down the price of electrical energy, making PEM electrolysis extra economically viable.

Conclusion

With continued improvement and funding, PEM electrolysis has the potential to contribute considerably to lowering the carbon footprint of the ammonia manufacturing trade and to the worldwide transition towards a extra sustainable and environmental pleasant economic system.

Furthermore, advances in supplies science and engineering, in addition to the rising availability of renewable power sources, are anticipated to drive down prices and enhance effectivity and sturdiness.

to know extra in regards to the creating applied sciences in your trade vertical? Get the newest market research and insights from BIS Analysis. Join with us at [email protected] to be taught and perceive extra.

[ad_2]

Source link